EUROPACK

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to EUROPACK

Thermoforming

Europack is India’s leading Thermoforming packaging manufacturer Company, serving customers worldwide. Europack develops and manufactures a wide range of medical packaging and thermoformed products. We always work closely with our customers, supporting them with our wealth of experience.

Thermoforming can be used to produce attractive box inserts and interiors. The insert can be tailored to the shape of the product to be packed. This ensures a perfect presentation and protection of the product. These inserts can be made from flock film for velvet- like appearance.

With the help Thermoforming Europack transport and assemble trays for any industry, which is looking to

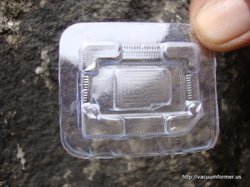

Vacuum Forming

Vacuum Forming Packaging

This is a type of forming which is used for providing packing solutions to various industries that require small or large quantities. These trays are used in food, pharmaceuticals, cosmetics, fisheries, blisters, 3 D pop up posters, & clamshell. Vacuum forming gives the customer complete flexibility in terms of product, design, size & quantity.

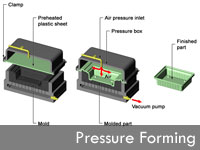

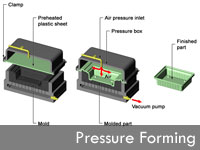

Pressure Forming

Pressure Forming Process

Pressure forming involves forcing a hot plastic sheet against a mold by introducing compressed air to the sheet's outer side. Europack, the leading pressure forming manufacturer, recommends pressure forming when your custom plastic enclosure requires features that cannot be achieved by vacuum forming alone.

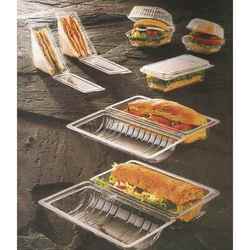

Food Packaging

Europack can efficiently and cost-effectively produce a wide variety of convenient packages and packaging trays for the food industry. We offer customers a variety of materials conforming to FDA and USDA standards including polystyrene, polypropylene, PET & PVC. We are manufacturer of vacuum formed food packaging trays and other food packaging materials. Through constant innovatio

Pharmaceutical Packaging

Europack is committed to delivering high quality precision thermoforming packaging services to the medical and pharmaceutical industries. We are manufacturer and supplier of pharmaceutical packaging products and medical packaging products. We work closely with our customers to generate creative, cost-effective solutions for their toughest packaging applications. Europack also stocks a large variety of standard medical trays for immediate delivery. Commonly used materials include FDA approved high-impact polystyrene, PET, PVC, polypropylene and those with sterilizable, anti-static or conductive properties.

Transparent Packaging

Transparent Clear Plastic Boxes

We have developed our core competence in the manufacturing of high quality transparent clear plastic boxes. Our plastic boxes are durable, lightweight. We specialize in manufacturing custom transparent clear plastic boxes to suit our clients' specifications.

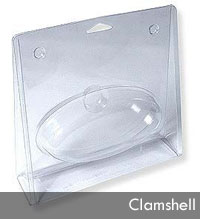

Clamshell Packaging

This is one type of packing that Europack specializes in. This is the packing used in the export markets extensively. We have a huge base of ready to use designs and sizes available with us which will be given to you on demand. This is a packing which can stand alone without any support as a display or selling unit on the counter, we can also hang it with a notch on the top of the blister. This packing does not require any other machine operations of sealing or pouching to complete its packing thus this is the packing of the future and a more reliable concept in the future. This kind of packing requires good tooling and precision machines to give the right hinge formation and tight locking which is not available in India for now, but our imported machine can give the perfect clamshell with zero defects.

Blister Packaging

Blister Trays Manufacturer

Heat seal blister The blister is sealed to the blister card by heat and pressure. The card has a heat activated coating. Sealing requires a blister sealing unit.

Cold seal blister : We also provide blisters for cold seal format which is a recent trend in blister packs these days. Cold sealing is used as a tamper proof packing for specialty industries and specific products which are heat sensitive.

Frozen Food Packaging

Frozen Food Packaging

We at Europack Plast Pvt. Ltd. specialise in the manufacturing of food grade packing materials that can withstand upto -40°c. These trays are made of materials using special additives which makes the product Very tough thus enhancing the durability of the items kept inside in extreme conditions. These trays are a lifeline in the Frozen Food market as the products have to pass through various channels at freezing temperatures. These trays are a great substitute to the otherwise cumbersome packing that was traditionally used. They also give the product great asthetic value.

P.V.C. Fills

Description / Specification of P.V.C. Fills

We are involved in offering a wide range of P.V.C. Fills to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of P.V.C. Fills. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Biscuit Cosmetic And Stationary Tray

We manufacture biscuit trays, plastic biscuit trays, plastic biscuit container, food trays with compartments, food trays with lids, food trays for parties, food tray packaging, food tray supplier, plastic chocolate trays, chocolate tray manufacturer, cake trays, cake tray suppliers, cake tray with lid, cake trays with lids, Dome lid, Folding boxes, Clamshells, Pastry boxes, Pastry tray, Chocolate moulds, Food service containers, plastic trays, plastic serving trays, plastic egg trays, plastic trays for food, plastic trays suppliers, plastic trays manufacturer, plastic trays with dividers

Plastic Tray P.V.C. Pet Hips Trays

We manufacture Plastic Tray PVC, PET and HIPS Trays. The types of material we can vacuum form are:

PET - Polyethylene Terephthalate (# 1 Plastic)

HDPE - High-Density Polyethylene (# 2 Plastic)

PVC - Poly Vinyl Chloride (# 3 Plastic)

LDPE - Low-Density Poly Ethylene (# 4 Plastic)

PP - Poly Propylene (# 5 Plastic)

PS - Poly Styrene (# 6 Plastic)

ABS - Acrylonitrile Butadiene Styrene

PC - Poly Carbonate

Vial Tray

Description / Specification of Vial Tray

We are involved in offering a wide range of Vial Tray to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Vial Tray. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

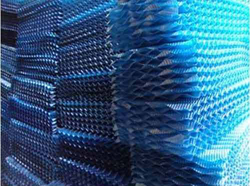

Honeycomb Fills For Cooling Tower

Technical Data :

1. Cooling Tower Application : Counterflow

2. Flute Height 12 MM

3. Longitudinal Pitch 38 MM

4. Spiral Angle : 28 Degree

5. Standard Sheet Size (L X W) : 600 MM X 300 MM

6. Max Recco Fill Sheet Size (L X W) : 1,800 MM X 600 MM

7. Surface area per unit Volume : 250 sq m / cu m OR 76 sq ft / cu ft

8. Max continuous operating temp : 55 Degree Cent / 131 Deg Farenheit

9. Standard fill sheet thickness : 0.22 MM OR 0.008”

10. Standard Weight of the fill pack : 800 GMs

11. Fills Colour : Blue

12. Edge Folding : Double

Plastic Packing Tray

We manufacture plastic trays, packaging trays in PVC, HIPS, PET, PP, HDPE, ACRLIC, PC etc

Other Information

Pay Mode Terms: L/C (Letter of Credit)

F. O. B. Price Order: 1 USD

Minimum Order Quantity :

10,000 Piece/Pieces

Port of Dispatch: Mumbai

Production Capacity: 100,000

Delivery Time: 3 Weeks

Packaging Details: Export quality box packing

P.V.C. Blister Tray

PVC Blister Tray

Types of material we can Vacuum form:

PET - Polyethylene Terephthalate (# 1 Plastic)

HDPE - High-Density Polyethylene (# 2 Plastic)

PVC - Poly Vinyl Chloride (# 3 Plastic)

LDPE - Low-Density Poly Ethylene (# 4 Plastic)

PP - Poly Propylene (# 5 Plastic)

PS - Poly Styrene (# 6 Plastic)

ABS - Acrylonitrile Butadiene Styrene

PC - Poly Carbonate

Mobile Accessory Blister

Blister carded packing is another popular packing made for the retail sector. Blister gives the card a more robust look, handling becomes easier, products are fully protected and therefore demand is relatively better. Blisters are available in various thickness starting from 15 micron to 50 microns.

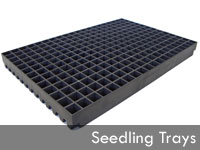

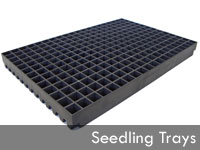

Nursery Tray

Description / Specification of Nursery Tray

We are involved in offering a wide range of Nursery Tray to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Nursery Tray. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Material Handling Trays

Material Handling Trays

We manufacture industrial trays in PVC, ABS, PP, HIPS, PET, ACRYLIC

Other Information

Pay Mode Terms: D/P (Documents Against Payment), T/T (Bank Transfer)

F. O. B. Price Order: 1 USD

Minimum Order Quantity:

10,000 Piece/Pieces

Port of Dispatch: Mumbai

Production Capacity: 100,000

Delivery Time: 3 Weeks

Packaging Details: Wooden Box Packing

Packaging Trays

Description / Specification of Packaging Trays

We are involved in offering a wide range of Packaging Trays to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Packaging Trays. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Vacuum Forming Machines

“Automatic Vacuum Forming Machine” EP 1420 with forming area 14” X 20” (with Ceramic Infrared Heaters, Output 10 cycles/min, & Power Consumption only 10 kW) With “Hydraulic Cutting Press” for online Cutting

Other Information

Pay Mode Terms: D/P (Documents Against Payment), T/T (Bank Transfer)

Minimum Order Quantity: 1 Piece

Port of Dispatch: Mumbai

Production Capacity: 10

Delivery Time: 4 weeks

Packaging Details: Export quality

Hips Sheets

HIPS Sheet

HIGH IMPACT POLYSTYRENE (HIPS) HIPS SHEET:

High Impact Polystyrene sheet (HIPS SHEET) is a versatile, cost effective material.

HIPS single and multilayer sheet structures are engineered

from the toughest polystyrene resins to add a superior balance of

enhanced properties for color control, higher gloss, UV protection,

appearance, stiffness, deep-draw formability, and high impact strength.

We offer several sheet grades of High Impact Polystyrene,

custom made for your market application: FEATURES AND BENEFITS OF HIPS SHEET:

Good impact strength

Easy to process

Good depth of draw ratio

Good dimensional stability

Fully recyclable with minimal loss in properties

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.